Luxury Finishes

Metallic Foiling

Are you seeking for unique packaging boxes to make your goods stand out? Metallic Foiling is the foremost easy way to go. With an extensive range of options, metallic foiling creates a striking visual effect that makes your product packaging pop. Metallic Foiling makes your packaging eye-catching and shining which will attract and impress the customer in a competitive market. The Metallic Foiling Process is called Electrostatic Deposition which coats the surface of your product packaging with a thin layer of metal foil. It is applied using heat and pressure to the surface of your product. At Custom Boxes Wholesale, we have a wide range of Metallic Foil options for you to choose from, including gold, silver, copper foil, and others. Each Metallic Foil has different properties that make it ideal for different applications. For example, gold and silver are both very reflective. This means that if you're looking to make eye-catching packaging for luxury products, gold will work well, but if you want something that will last longer and be more affordable, silver would be a better choice.

Holographic Foiling

Custom boxes with Holographic Foiling are a great way to add some pizzazz to your packaging. You can use them to give your brand a decorative look, or you can use this foiling effect to make your products exclusive and desirable. During the Holographic Foiling Process, a thin layer of Holographic Foil is applied to the surface of a product using heat. This Holographic Foil has a unique quality in which it reflects light at different angles, creating an effect that is both vibrant and subtle. This creates an iridescent and sparkling effect on the product packaging. Holographic Foils by Custom Boxes Wholesale, are made of a thin, transparent film that can be applied directly over your printed design. The foil comes in various colors and patterns, including gold, silver, and rainbow. You can choose between matte or gloss finishes for the foil. Holographic Foiling is used extensively in the cosmetic industry to make amazing packaging with a stunning effect. This type of packaging not only adds glamor to your product but also increases its perceived value. You can also use Holographic Foiling as an indicator of quality.

Aqueous Coating

Aqueous Coating is a great way to add an extra layer of protection to your custom boxes. This is one of the most popular environmentally friendly choices among the finishing methods used for custom product packaging. It can be applied to any kind of box including cardboard, rigid, kraft, corrugated, and others. It gives your packaging a glossy look and a water-resistant finish. We offer custom Aqueous Coatings for your custom boxes that will ensure that they look as good as new, no matter how many times they've been handled or shipped. The coating is used to protect the surfaces of the box from moisture and contaminants and provide a smooth surface. It feels smooth and silky touch and gives your custom boxes a beautiful look. Our different types of coating include:

- Pencil Receptive Coating

- Soft Touch Coating

- Dry Erase Coating

- Gloss Coating

- Matte Coating

- Satin Coating

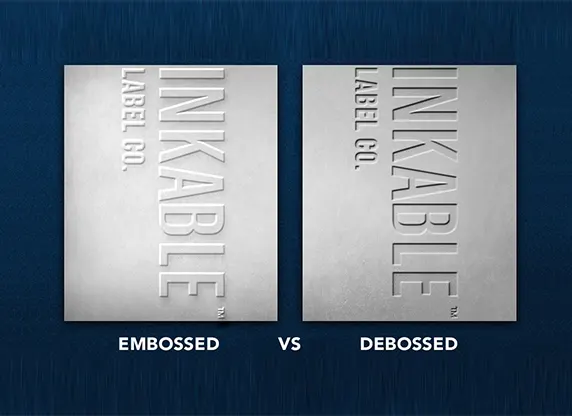

Embossing/Debossing

If you want an exclusively raised/indented silhouette of your logo, text, or art design, Embossing/Debossing is something you need on packaging boxes. This process uses heat and pressure to create a raised pattern on the surface of your packaging, which adds another dimension to your brand identity. Embossing can be done with ink or foil and creates a beautiful effect that makes your product seem more high-end. It is done on custom boxes which adds a special element of style and makes sure that your logo and branding get immediate attention while leaving an unmatched yet memorable experience. Debossing, on the other hand, is a process in which a design is pressed into the surface of paper or other material by applying pressure to the back of it. This process can be used to make custom boxes more appealing and eye-catching. You can add artistic elements, logos, or text to your packaging. At Custom Boxes Wholesale, we offer Embossing and Debossing together to create even more complex designs or textures. We can produce even more eye-catching and premium patterns by combining them with additional printing techniques like foil stamping, matte lamination, and spot UV finishing.

Gloss vs Matte Lamination

Gloss Lamination is a type of coating that is applied to the surface of a box to increase its durability, as well as its visual appeal. It is an excellent and affordable choice for enhancing the image of your product, as it creates an attractive finish on your product packaging. Gloss lamination adds a layer of promote durability than matte lamination. If you want to add an extra layer of protection along with the glare on a relatively low budget, try the Gloss Lamination of the packaging box. Matte lamination is a smooth finish that is popular for its ability to reduce glare on the surface of your product. The matte surface creates a unique effect. It also creates a barrier between your product and the environment, protecting it from moisture and other damaging elements. It's the perfect way to add a bit of style and sophistication to your packaging. Protection that can keep your products safe through rough handling during transit and storage. If you want to give a professional and elegant look by using subtle and muted colors, Matte Lamination is something you need for your product packaging

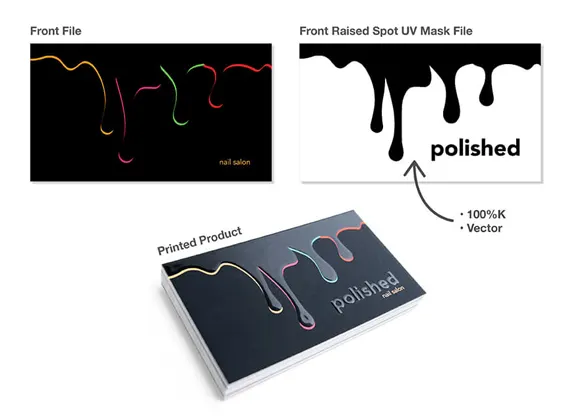

Raised Spot UV

Raised Spot UV is ideal for impactful brand image and effective marketing for the product. The highlights and added touch of style to your product packaging are achieved through this technique. It can be applied to the box's front, back, and sides. It is a type of spot color printing achieved by coating the paper with a transparent varnish and then exposing it to a standard black-and-white halftone screen. The raised areas on the coated paper, which correspond to areas of the screen that are opaque, receive more exposure than the other areas, resulting in an image being printed at only those points. Our Raised Spot UV is highly demanded by customers in their custom wholesale packaging because of its good resistance to abrasion, moisture, and other environmental conditions, and its cost-effectiveness compared to other print forms. The raised spot UV gives the printed colors depth and helps them stand out from the surface. This is a great approach to draw attention to your company because it can be done using a variety of materials and colors. Spot UV is applied using our cutting-edge printing technology to the precise printed areas you wish to highlight. Only when you shine a light on it will this texture be visible, and you may use it to complement your logo or as a stand-alone design element.

Silk Lamination

Add a matte and soft velvety touch similar to peach skin to your packaging boxes with the Silk Lamination. This is a high-performance lamination for packaging and product protection—ideal for folding carton packaging or rigid packaging. It provides a glossy, scratch-resistant finish that is ideal for showcasing the beauty of your product. Silk laminated boxes enhance sustainability while adding value, prestige, and protection to an already beautiful design. We offer the highest quality lamination on a variety of materials including cardboard, corrugated fiberboard, paperboard, etc. This type of finish is great for businesses that want to create luxurious custom boxes that represent their brand values. Silk Lamination is suitable for various packaging and branding projects including retail packaging, custom invitations, presentation folders, hand tags, rack cards, invites, and more.